- Stock: In Stock

- Brand: ACCUD

- Model: AC531-014-01

- Weight: 0.10kg

- Dimensions: 66.00cm x 70.00cm x 70.00cm

- SKU: AC531-014-01

- UPC: 6009515870249

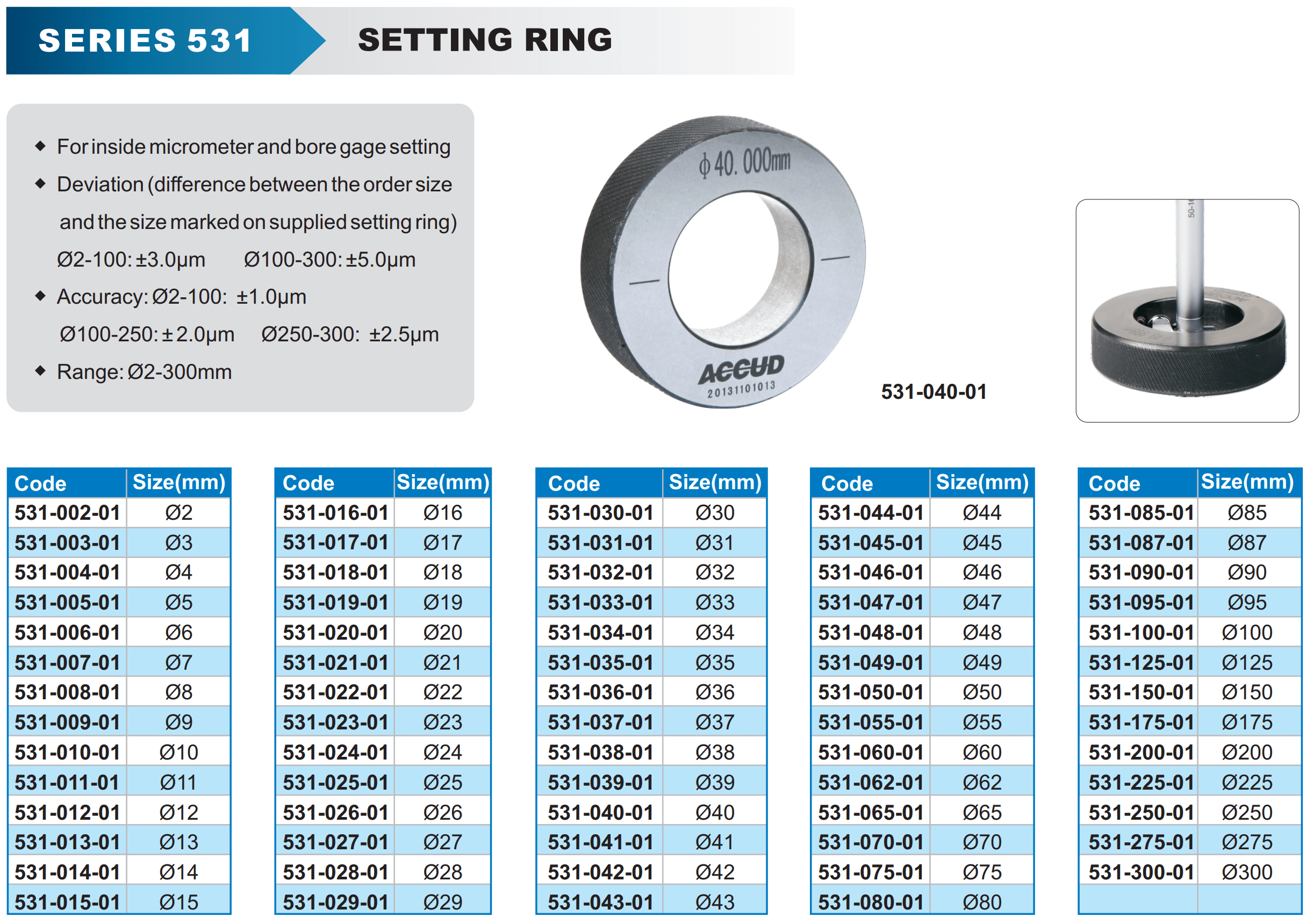

SERIES 531

Setting rings are most commonly used for setting bore gauges, this is the fastest most reliable method because the part to be gauged and the setting ring have the same geometric shape. Ring gauges are metrology tools that are used for gauging the outer diameters of pins, shafts, splines, fasteners, dowels, studs, and other machined cylindrical parts.

The ring gauge is a ring-shaped measuring instrument used to measure the outside diameter of cylindrical objects such as pins, shafts, splines, fasteners, dowels, studs, and other parts of the machine. Ring gauges are usually made of stable materials such as chrome plated tool steel and carbide which provide greater service life. This tool is very precise (exceedingly tight tolerance) which is used as an outer diameter gauge.

- For inside micrometer and bore gage setting

- Deviation (difference between the order size and the size marked on supplied setting ring) ±3.0µm

- Accuracy: ±1.0µm

Specification summary

- For inside micrometer and bore gage setting

- Deviation (difference between the order size and the size marked on supplied

setting ring)

- Ø2-100: ±3.0µm

- Ø100-300: ±5.0µm

- Accuracy: Ø2-100: ±1.0µm

- Ø100-250: ±2.0µm

- Ø250-300: ±2.5µm

- Range: Ø2-300mm

The main function of the ring gauge is to determine by 'go' or 'no-go' whether the measured part is in accordance with the specified dimensional tolerance. The use of ring gauges allows inspections of machine parts to be made very quickly without the need to use micrometers, calipers, thickness gauges, or other measuring instruments which can take longer to conclude its quality.

Ring gauges are also effective for checking roundness at higher levels. Measurements with this tool are used as a standard to set the bore gauge, which can then be used to determine whether there are deviations from the nominal size.

How to Use a Ring Gauge

Here is how to use a ring gauge:

- Select a ring gauge with the appropriate diameter size.

- Before use, the surface of the ring gauge is cleaned with a dry cloth.

- The levers and washers must be securely attached so that the rotation with respect to the substrate can be measured and produce the appropriate level of measurement precision, for example at the zero setting when measuring the internal diameter.

- The ring gauge only needs to be attached between the lever and the ring.

- Then record the diameter and scale that you will apply to other objects to explain the results of measuring the scale.

- After use, wipe again with a dry cloth.

- Store the ring gauge in a place where the humidity and temperature are stable.

It is particularly important to keep the ring gauge clean and free from dirt (such as oil, chips, fingerprints, etc.). These impurities can affect the performance of the ring gauge, not only during calibration, but also in screw thread inspection applications. The regular use of a tube bristle brush whose size corresponds to the main diameter of the ring gauge will help keep the ring gauge from becoming filled with dirt during use.

Unlimited Blocks, Tabs or Accordions with any HTML content can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc. You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.